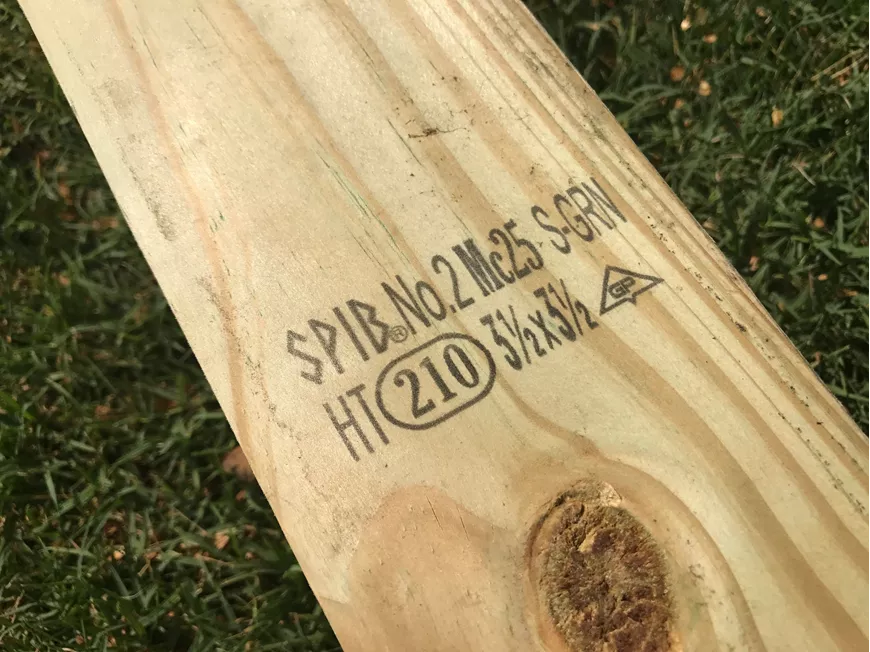

How to Read Lumber Grade Stamping

Any lumber you purchase should have a grade stamp or end tag. These markers provide a lot of important information related to the characteristics of the wood. Each piece of lumber will be visually or mechanically inspected according to the number of defects that are present and graded accordingly to meet consistent visual and structural standards.

The stamp will include a seal that identifies which certified agencies' rules were used in grading the lumber as well as identifying the mill where the lumber was processed. The species of wood will be identified in an abbreviated form and the grade designation will be placed in the center of the stamp. There are many industry-specific grades for different wood products. The most common are FAS, Select, #1 Common and #2 Common, from best to worst. The surface texture of each face will be listed as either S for smooth or RS for rough sawn. The moisture content will be referenced by the abbreviations Grn for green (containing more than 19% water weight), Dry (containing less than 19% water weight), or KDAT (kiln-dried after treatment).

Using grade stamp information will be helpful when selecting your materials, but the markings themselves act as a visual defect on the surface of a deck. You may be able to turn the board over to hide the stamp. Otherwise, the only way to remove grade stamps from lumber is to sand the board.

Capped Composite Decking

What is capped composite decking? It's a great option if you like the look of wood but not the maintenance. Learn about capped composite at Decks.com.

Fiberon

Fiberon low maintenance decking is manufactured by Fiber Composites, LLC in New London, NC

Aluminum Decking Reviews, Pros & Cons, and Costs

Everything you need to know about aluminum decking including pricing information, top brands, and the types of aluminum decking. Get started with Decks.com.

Cutting a Concrete Pad

Learn how to use a concrete saw to cut a hole in a patio slab to install a deck footing.

Retaining Walls

Avoid problems related to digging deck footings near retaining walls. Learn some tips from the pros for how to handle these difficult situations.

Can I use pier blocks?

Our inspector explains the pros and cons of using pier blocks for deck foundations.

More Helpful Resources

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

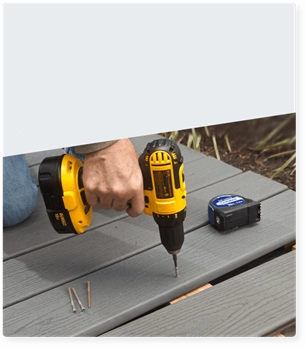

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights

Is Trex Decking Worth the Investment? Expert Insights and Reviews

Discover why Trex decking is worth the investment. Learn about its durability, low maintenance, eco-friendliness, and the long-term value it adds to your home.

Comparing Trex Decking Lines: Signature vs Lineage vs Transcend vs Select vs Enhance

Discover the four main types of Trex decking: Transcend Lineage, Transcend, Select, and Enhance. Check out our review to learn what sets each apart.

How many footings do I need?

Avoid a wobbly deck! Learn how to calculate the right number of footings to keep your structure safe and solid.

Protecting From Collapse

Learn how to use cardboard sonotubes and hole covers to protect your deck footing holes from caving in and flooding before pouring concrete.

Deck Bracing

Learn how to install knee bracing in-between your deck support posts to provide extra strength against high winds and to prevent racking forces for tall decks.

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights