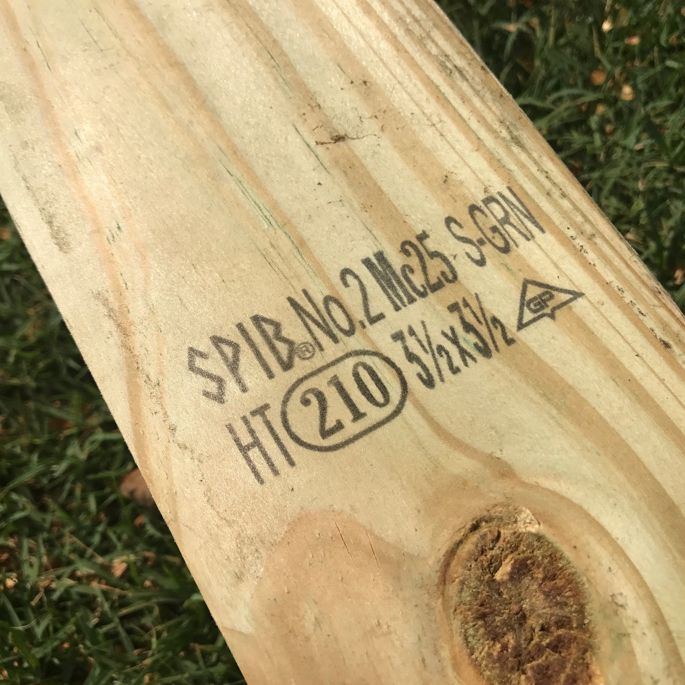

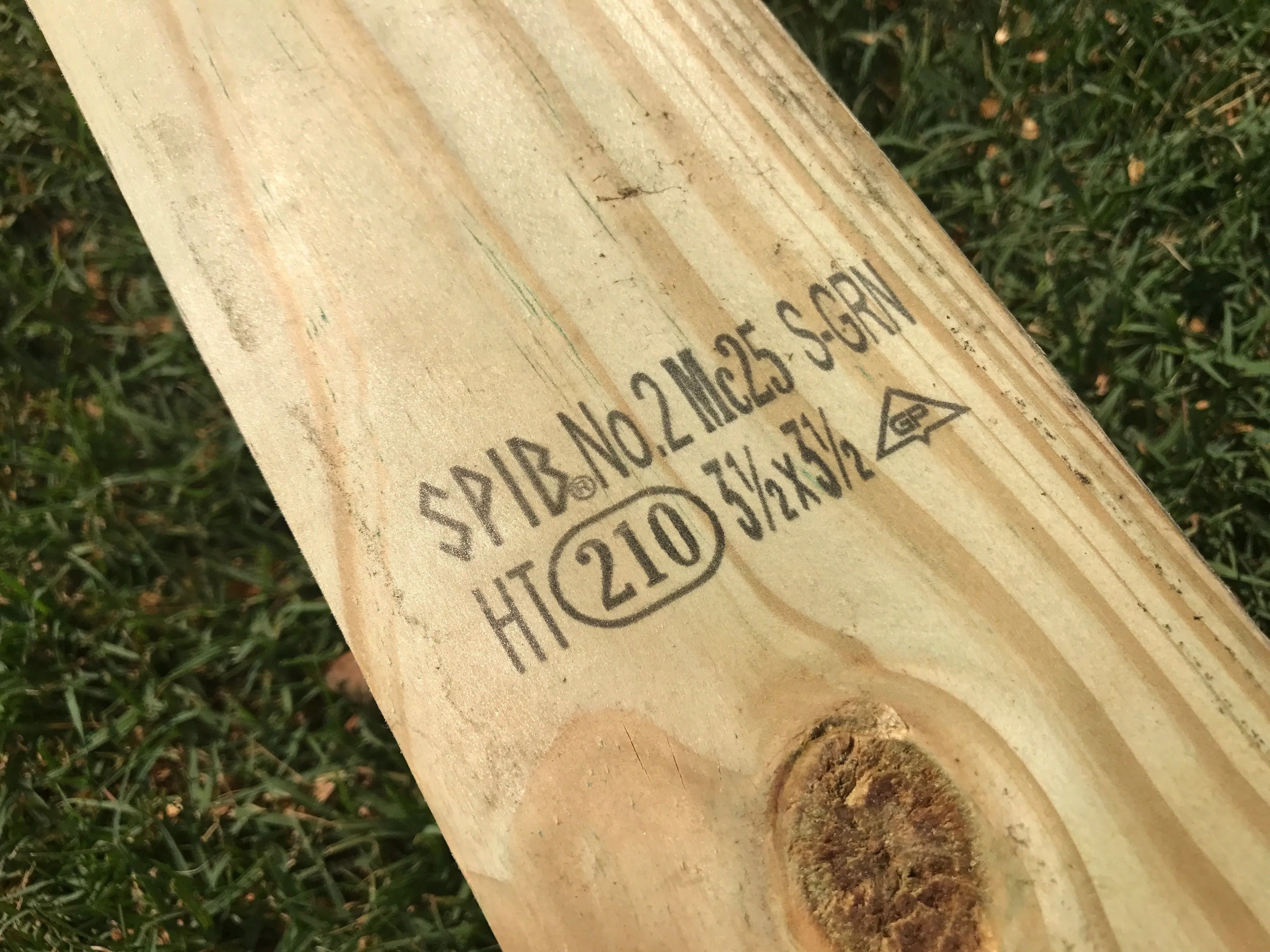

Any lumber you purchase should have a grade stamp or end tag. These markers provide a lot of important information related to the characteristics of the wood. Each piece of lumber will be visually or mechanically inspected according to the number of defects that are present and graded accordingly to meet consistent visual and structural standards.

The stamp will include a seal that identifies which certified agencies' rules were used in grading the lumber as well as identifying the mill where the lumber was processed. The species of wood will be identified in an abbreviated form and the grade designation will be placed in the center of the stamp. There are many industry-specific grades for different wood products. The most common are FAS, Select, #1 Common and #2 Common, from best to worst. The surface texture of each face will be listed as either S for smooth or RS for rough sawn. The moisture content will be referenced by the abbreviations Grn for green (containing more than 19% water weight), Dry (containing less than 19% water weight), or KDAT (kiln-dried after treatment).

Using grade stamp information will be helpful when selecting your materials, but the markings themselves act as a visual defect on the surface of a deck. You may be able to turn the board over to hide the stamp. Otherwise, the only way to remove grade stamps from lumber is to sand the board.