As an Amazon Associate, Decks.com earns from qualifying purchases from the links in this post.

Deck Building Tools: What You'll Need

Tools for Layout and Measuring

To build a quality deck, you will check constantly to be sure its parts are level, plumb and square. The following deck tools and equipment will help you with precision and more while you build.Tape Measures & Chalk Lines

Framing and Speed Squares

Excavation and General Tools

For excavating, hand tools can usually do the job, though, you may want to hire a landscaper or rent an earth-moving or post hole-digging machine for very large jobs.Shovels

Pipe and Squeeze Clamps

Pry Bars and Wrenches

Tools for Cutting

Building a deck does not call for cuts as precise as those for cabinetry, but your cuts should be very accurate.Circular Saw

Jigsaw

Reciprocating Saw

Knives and Shears

Table Saw

Tools for Fastening

A power nailer works much faster and easier than a hammer, and prevents denting often produced by mishits when hand nailing. Still, a hammer is often used for driving joist-hanger nails and for getting into tight areas. A nail set extends your reach when nailing. A teco nailer, which attaches to an air compressor like a power nailer, can also be used for driving small nails for joist hangers and other hardware.An 18- or 20-volt cordless drill has become one of the most popular fastening tools. An impact driver makes it easier to drive screws and bolts very firmly, and if you plan to install decking with face screws, consider using a speed driver. This tool features a clip you can load with screws in order to drive a lot of them quickly, and has an extender that enables you to do the job while standing up.

Tools for Shaping and Smoothing

Use a router with a roundover bit or a decorative bit to ease sharp edges and creative custom looks. A belt sander is the most powerful sanding tool, but should be used carefully so you don’t dig into the wood. A random orbit sander is also effective at smoothing and removing stains, but is safer to use. A hand sander is also a viable option to get the job done, too.This page contains affiliate links. If you choose to purchase after clicking a link, Decks.com may receive a commission at no extra cost to you.

How to Decorate Deck Support Columns

Browse some examples of decorative deck support posts for tall decks.

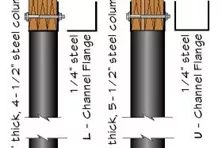

How to Use Steel Metal Deck Support Posts and Columns

Steel deck posts with base plates can be used as an alternative to wood posts for supporting your deck.

Deck Blocking: Spacing, Methods, and How to Install Like a Pro

Learn the importance of deck blocking and how to install it when building your deck.

How to Install Decking Over Existing Concrete Slab, Patio, or Porch

Discover the best techniques to build a deck over concrete, ensuring proper drainage and stability, while creating a beautiful outdoor space.

How to Install and Fasten Deck Fascia

Installing deck fascia can be easy if you have the proper tools, fasteners, and practical information that you’ll find right here.

How to Build a Floating Deck

A deck does not need to be attached to a house. Building a floating deck allows you the opportunity to create that perfect outdoor space anywhere on your property. Find out if a floating deck is the best option for your new outdoor oasis.

More Helpful Resources

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

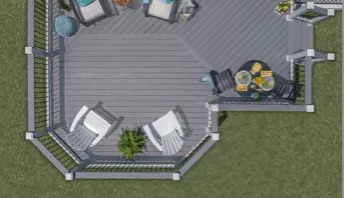

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights

Why is Joist Protection so Important for Your Deck?

If you’ve ever seen a piece of wood left out in the weather for any period of time, you know what happens: decay. Whether through wet rot, insect damage, or mildew, the fibers begin to break down.

How to Use Steel Metal Deck Support Posts and Columns

Steel deck posts with base plates can be used as an alternative to wood posts for supporting your deck.

How to Build a Ground Level Deck

Adding a ground level or floating deck to your home may be the perfect addition to your outdoor space. Learn how to build a ground level deck at Decks.com.

What to Consider When Building A Wrap-Around Deck

Looking to add a wrap-around deck to your home but unsure of what the process involves? Check out this guide to learn more about top considerations when building a wrap-around deck.

How to Install Composite Decking

Learn about how to install composite decking. Topics include expansion and contraction issues and hidden fastener systems.

How to Install and Fasten Deck Fascia

Installing deck fascia can be easy if you have the proper tools, fasteners, and practical information that you’ll find right here.

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights