Engineered Deck Beam

It is possible to increase your beam spans and eliminate footings and structural posts for your deck by using engineered laminated beams, heavy timbers or steel I girder beams. Using an engineered beam will reduce the number of posts blocking windows under a deck or may provide a clear span for a deck over a driveway. These beams are designed much stronger and more stable than standard dimensional lumber beams. It is possible to achieve spans up to 20 feet. Engineered beams must be treated for use outdoors.

Glulam beams are manufactured by gluing layers of dimensional lumber together. Parallam beams are manufactured by gluing together aligned wood stands and bonding them using a microwave process.

Large, solid sawn lumber timbers, referred to as “heavy timber” are available, but may be expensive to obtain in decay-resistant species if desired or necessary.

Your local lumberyard should be able to help you size and order engineered deck beams. Bring them a plan of your deck with dimensions showing the position of all your footings and posts. They will send your information to a design center where an engineer will specify the proper size engineered beam. They will also provide a report which will be useful in applying for building permits. Engineered beams are more expensive than standard deck framing materials but are usually the only option for projects that demand long beam spans.

Glue Laminated Timber Beams Spans

| Joist Spans | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Stress Class | Width | Depth | 6' | 8' | 10' | 12' | 14' | 16' | 18' |

Balanced or Unbalanced 20F -1.5E And Higher Grade Cedar | 3-1/2" | 9-1/2" | 12'-2" | 10'-6" | 9'-4" | 8'-6' | 7'-10' | 7'-4" | 6'-11" |

| 11-7/8" | 15'-2" | 13'-1" | 11'-8" | 10'-8" | 9'-10" | 9'-2" | 8'-8" | ||

| 16" | 17'-10" | 15'-5" | 13'-9" | 12'-7" | 11'-7" | 10'-10" | 10'-2" | ||

| 5-1/4" | 9-1/2" | 18'-0" | 16'-8" | 14'-10" | 13'-7" | 12'-6" | 11'-8" | 11'-0" | |

| 11-7/8' | 18'-0" | 18'-0" | 17'-6" | 15'-11" | 14'-9" | 13'-9" | 13'-0" | ||

| 16" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | 16'-10" | 15'-9" | 14'-10" | ||

Unbalanced 24F - 1.8E Douglas Fir - Larch or Southern Pine | 3-1/2" | 9-1/2" | 13'-11" | 12'-1" | 10'-9" | 9'-10" | 9'-1" | 8'-6" | 8'-0" |

| 11-7/8" | 17'-5" | 15'-1" | 13'-5" | 12'-3" | 11'-4" | 10'-7" | 10'-0" | ||

| 14" | 18'-0" | 17'-9" | 15'-10" | 14'-5" | 13'-4" | 12'-6" | 11'-9" | ||

| 5-1/4' | 9-1/2" | 18'-0" | 18'-0" | 17'-1" | 15'-7" | 14'-5" | 13'-6" | 12'-8" | |

| 11-7/8" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | 17'-0" | 15'-10" | 14'-11" | ||

| 16" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | 17'-0" | ||

Balanced 24F - 1.8E Douglas Fir - Larch or Southern Pine | 3-1/2" | 9-1/2" | 13'-11" | 12'-7" | 11'-8" | 11'-0" | 10'-5" | 9'-11" | 9'-7" |

| 11-7/8" | 17'-5" | 15'-10" | 14'-8" | 13'-9" | 13'-1" | 12'-6" | 12'-0" | ||

| 14" | 18'-0" | 18'-0" | 17'-4" | 16'-3" | 15'-5" | 14'-9" | 14'-2" | ||

| 5-1/4" | 9-1/2" | 18'-0" | 18'-0" | 17'-4" | 16'-3" | 15'-5" | 14'-9" | 14'-2" | |

| 11-7/8" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | 17'-6' | 16'-9" | ||

| 16" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | 18'-0" | ||

Assumes 40 psf live load, 10 psf dead load, L/360 simple span beam deflection limit, cantilever length/180 deflection limit. Glued laminated timber shall be naturally durable or preservative treated with an oil-borne treatment in accordance with AWPA U1.

How to Decorate Deck Support Columns

Browse some examples of decorative deck support posts for tall decks.

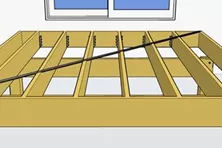

How to Brace a Swaying Deck

Learn how to install a diagonal brace on your deck frame to prevent racking. Check out our detailed image.

Framing a Deck Parallel to a House

Learn about an alternative framing method that allows you to install your decking perpendicular to the house and makes the deck free standing.

Decking Patterns

Installing your decking at a 45-degree angle is a popular style for decks. This can be done to reduce decking seams or just for appearance.

Tile decking

Installing tile over a standard deck frame in an exterior environment is a recipe for trouble.

Best Time to Build a Deck

People often wonder when the best time to build a deck is. Learn why building a deck in winter or fall might be your best bet.

More Helpful Resources

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

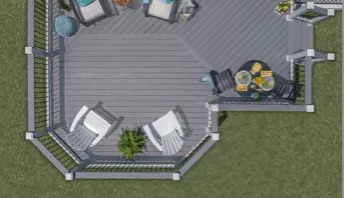

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights

Why is Joist Protection so Important for Your Deck?

If you’ve ever seen a piece of wood left out in the weather for any period of time, you know what happens: decay. Whether through wet rot, insect damage, or mildew, the fibers begin to break down.

How to Install Deck Post Wraps and Sleeves

Learn how to install trim or post sleeves over your pressure-treated support posts for a cleaner finish and to protect the material from checking.

How to Extend a Deck

A deck extension is a great option when you feel like you need more outdoor space. Learn the step-by-step process of extending an existing deck.

How to Demolish & Remove a Deck

At some point, it might become necessary to remove an old deck, due to age or condition. Learn more about what's involved in a deck demolition and removal project.

Best Time to Build a Deck

People often wonder when the best time to build a deck is. Learn why building a deck in winter or fall might be your best bet.

10 Common Deck Building Mistakes & How to Avoid Them

Building a deck can be a complicated process. Learn how to avoid falling into common deck building pitfalls with tips and advice from the experts at Decks.com.

Explore Articles by Topic

Footings

Information related to installing frost footings for decks

Framing

Learn structural framing methods

Decking

Learn about wood and composite decking materials

Stairs

An in-depth look at the complex issue of how to build stairs

Railings

How to install guardrails and handrails to meet IRC code

Features

An overview on water drainage, benches, planters and lights

Design

The basics of deck design

Planning

Learn about permits and working with contractors

Porches & Patios

Build a covered deck to enjoy all seasons

Ledger

Proper attachment techniques

Care

Maintain your deck to maintain your investment

Materials

An overview on water drainage, benches, planters and lights